Jetnuts JNS

Grease Gun Actuation

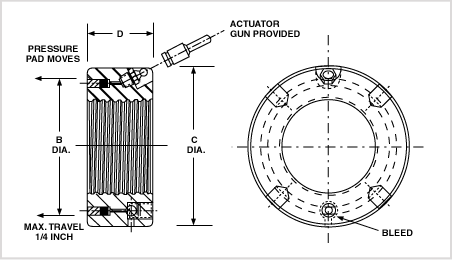

To Put on Jetnut

- Spin Jetnut on by hand until snug then back off 0.015/0.030.

- With 1/4 hex key tighten bleed.

- Insert grease gun on fitting and pump until handle is firm (overpressurization is impossible).

To Remove Jetnut

- Using 1/4 hex key, loosen actuate screw marked bleed to release pressure "DO NOT REMOVE SCREW."

- Tighten Jetnut by hand to reset pressure pad system.

- Jetnut can now be removed by hand.

Warnings

- Do not actuate nut when not in position.

- Grease gun must be refilled with air free grease.

Example: BP Oil Energrease LS-EP2 Mobil Mobilux EP2.

| Part # | Max Thread A | Pressure Pad Diameter B | Body Diameter C | Thickness D | Thrust Pressure Using 10,000# Actuator |

| JNS3750 | 2" | 2 3/4" | 3 3/4" | 2" | 19,640 |

| JNS4500 | 2 1/2" | 3 3/4" | 4 1/2" | 2" | 27,740 |

| JNS5000 | 3" | 4 1/4" | 5" | 2" | 31,500 |

| JNS5500 | 3 1/2" | 4 3/4" | 5 1/2" | 2" | 35,300 |

| JNS6000 | 3 3/4" | 5" | 6" | 2" | 37,300 |

| JNS7000 | 4 3/4" | 6" | 7" | 2" | 45,100 |

| JNS8000 | 5 3/4" | 7" | 8" | 2" | 53,000 |

| JNS9000 | 6 3/4" | 8" | 9" | 2" | 60,900 |

| JNS10000 | 7 1/2" | 9" | 10" | 2" | 68,700 |

| JNS11000 | 8 3/4" | 10" | 11" | 2" | 76,600 |

| JNS12000 | 9 1/2" | 11" | 12" | 2" | 84,400 |

| JNS13500 | 10 1/4" | 12" | 13 1/2" | 2" | 137,700 |

| JNS14500 | 11 1/4" | 13" | 14 1/2" | 2 1/2" | 148,000 |

| JNS15500 | 12 1/4" | 14" | 15 1/2" | 2 1/2" | 160,000 |

| JNS16500 | 13" | 14 3/4" | 16 1/2" | 2 1/2" | 170,000 |

| JNS17500 | 14" | 15 3/4" | 17 1/2" | 2 1/2" | 181,000 |

Note: Extra charge for special threads, (square, buttress or metric), which are available. Custom design applications also available upon request.

Note: Use of any other grease fitting other than the special design Jerry Tools parts #1800 or #1900 high pressure leakproof grease fittings not recommended.

Note: All Jetnuts available in aluminum to reduce weight.

Note: JNS models available up to 48" DIA.